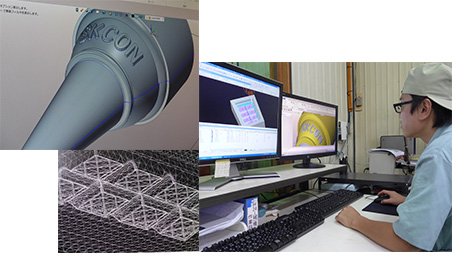

To manufacture intricately-shaped products, we have introduced a 5-axis processing machine.

When cutting metal, the 5-axis processing machine can approach the metal from arbitrary angles, unlike a conventional 3-axis processing machine.

Accordingly, it has enabled more complicated machining and higher-precision production, which was impossible with the 3-axis processing machine.

In addition, although the 3-axis processing machine needed to be reset whenever the cutting angles changed, the 5-axis processing machine enables multi-face machining with a single clamping operation, without the need for resetting.

In addition, although the 3-axis processing machine needed to be reset whenever the cutting angles changed, the 5-axis processing machine enables multi-face machining with a single clamping operation, without the need for resetting.

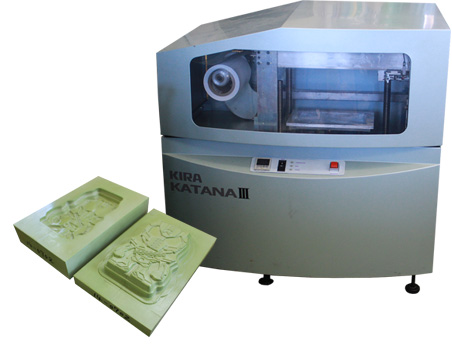

In order to pursue high-quality design and high precision, we make full use of a 3D CAD/CAM system to perform the operation from design to data creation within the same system.

Since we can easily check the shape of finished products on a computer screen, we can perform fine balanced adjustment. We can also decrease the number of product defects through prior simulation.

The 3D CAD/CAM system can express complex designs on curved surfaces, which was difficult to express with a 2D system, ensuring that we flexibly respond to the requests of customers.

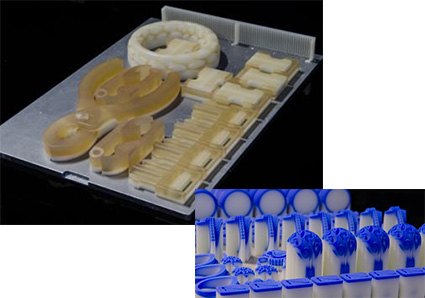

Even though we create data using a 3D CAD system, in the past we needed to implement various processes until we could finally confirm the functions of actual mock-ups. However, a 3D scanner/printer can easily create 3D mock-ups as easily as printing on paper sheets.

This leads to an overall reduction in the operational process and lower cost. By using the system, we can create mock-ups with fine detail and easily confirm their functions.

In this age of digital manufacturing, there is a whole range of products that are no different from one another, due to accelerated automation, computerization, and globalization. Accordingly, consumers cannot tell the difference between the products, no matter which companies manufacture them.

We have been involved in digital fabrication for 20 years, leading the way for other manufacturers, although 3D printers were not popular 20 years ago. Thus, we have for a long time created 3D models using paper based on computer data. Digital fabrication is a type of manufacturing process where materials are processed and shaped into products based on computer data.

Our manufacturing policy is to offer customers valuable products—not only products manufactured using digital fabrication but all our products—which are less susceptible to commoditization. We have continued to have a deep passion for manufacturing.

We have newly installed a cutting-edge 3D printer. We intend to apply our know-how in paper-based molding machines to this 3D printer. Making use of this technology, we aim to offer plastic resin models, which are created using the 3D printer based on CAD data, not only in the specific business field dealing with metal molds, but in a wide range of fields.

3D models are generated through a process in which materials are formed into a 3D shape using dedicated instruments based on designs drawn on a computer screen. Recently, 3D printers, which were developed in the US, are famous as dedicated instruments.

Commoditization refers to the state in which consumers do not think there are any differences in the products of competing manufacturers, because the originality of individual manufacturers is not reflected in their products.

Copyright@SUZUKI KENJI IRON WORKS Co ,Ltd Co Ltd.All rights reserved