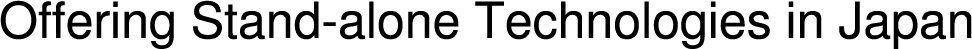

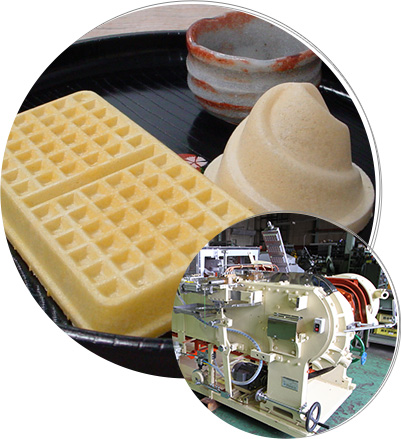

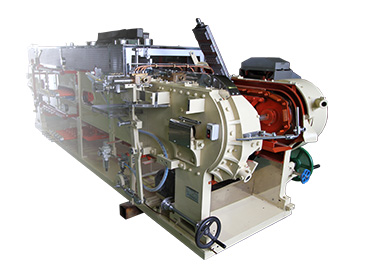

Since the company’s foundation in 1946, we have been mainly involved in the manufacturing and marketing of food production machines for ice cream cones and monaka ice cream wafers. We have also been involved in iron-related activities, including the machining of car parts.

In the field of monaka ice cream wafers, we have almost exclusively supplied food production machines to major confectionery manufacturers in Japan, based on the technologies and trust that we have developed over many years.

We market systems as well as machines. We aim to not only offer machines, but also disseminate technologies representing the “Made-in-Japan” brand both within Japan and abroad, integrating Japan’s unique food culture of monaka ice cream.

President and CEO

Shigero Suzuki

No two molds for monaka ice cream wafers ordered by our customers are alike. We carefully manufacture machines tailored to the needs of our customers one by one, deeply understanding their requests and proposing ideas as needed.

Helping customers realize their dream is our dream. To this end, we will work to improve the quality of our products and technologies to explore the fascinating world of food production machines.

We offer food production equipment that integrates all production processes from raw materials to finished products. We can also provide technical guidance to produce monaka ice cream products at the request of our customers, as well as Japanese-style know-how in production management.

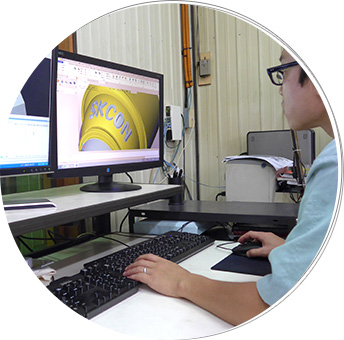

Various types of monaka ice cream products with novel designs can be produced. A 3D CAD/CAM system helps create new and original product trends. Moreover, the switch to new products can be done at low cost simply by changing metal molds using cutting-edge 3D scan technology.

By introducing a 3D processing machine and a 5-axis processing machine, we can offer confectionery machines with metal molds that can precisely match your product images to actual products.

Monaka ice cream wafers can be used for various other applications based on your ideas and ingenuity. Specifically, you can use monaka wafers as edible containers for sweets by filling them with chocolate, or create original products by combining them with various materials. Our machines can help you produce an elegant and beautifully curved shape for monaka ice cream products.

We can offer the whole process, from design to finished product, in a short delivery time by using 3D sample modeling technology.

Our machines are particularly excellent in mass production (productive performance).

The main body has a simple structure and suffers few mechanical faults, showing excellent durability, not including the metal molds and other nondurable parts.

With an over 60-year history of manufacturing automatic monaka baking machines, we possess a great deal of know-how in monaka baking technologies. We acquired a patent for our technology in 1980, and subsequently obtained an additional patent.

Monaka production technologies, which are unique to Japan, have been handed down from generation to generation over the years.

I am focusing efforts on improving the in-house environment. Although we are not a new company, I have worked to create an environment for young employees to make full use of their abilities. I am now involved in changing the company’s traditional structure. As part of my efforts, I have introduced the latest machines and a computer-automated measuring system at an early stage. I will strive to provide the young employees with the opportunity to work effectively with the concerted efforts of all company executives.

Kunio Suzuki

Corporate Adviser

The NC Division works toward improvement of the technical skills of individual employees. When manufacturing our products, we always place importance on the enhancement of speed, accuracy, simplicity, and safety. However, the foundation of manufacturing lies in human resources. I hope that more young employees as well as on-site staff members will work to further change the current situation.Kunio Suzuki

Corporate Adviser

The Automatic Confectionery Machine Division, which is mainly involved in manufacturing in-house products, exerts its originality and ingenuity to develop new products on a daily basis, inheriting the technologies that have been accumulated over a long time by our predecessors. In accordance with the changing times, all staff of the Automatic Confectionery Machine Division are working to create an environment in which young employees can play a central role in developing innovations by integrating state-of-the-art technologies and our accumulated know-how. We will make efforts to become a company in which individual employees can share the same company vision through manufacturing.Yasuro Suzuki

| Iron Works Founded | November 1946 |

|---|---|

| Company Established | February 1975 |

| Paid-in Capital | 20 million yen |

| President & CEO | Shigero Suzuki |

| Number of employees | 48 |

| Site area | 1850㎡ |

| Factory area | 1760㎡ |

| Scope of business | Manufacturing and marketing of ice cream cone production machines Manufacturing of prototypes of car parts and of engine-related parts Machining and assembly of machine tool-related parts Designing and manufacturing of other industrial machines |

| Main customers |

National Ice Cream Cone Association and its affiliated companies Car-part-related companies Washino Kiki Co., Ltd. |

| Banks |

Nishio Branch, Bank of Tokyo-Mitsubishi UFJ Isshiki Branch, Nishio Shinkin Bank Isshiki Branch, Okazaki Shinkin Bank |

| 1946 | Suzuki Kenji Iron Works founded as a confectionery machine manufacturer |

|---|---|

| 1949 | Developed automatic ice cream cone baking machine |

| 1956 | Began to focus on marketing based on the success of its development of automatic machines |

| 1959 | Obtained a patent for ice cream cone making machines |

| 1963 | Enhanced the lineup of in-house machines with a machine tool manufacturer (Washino Kiki Co., Ltd.) as a manufacturing partner |

| 965 | Strengthened the manufacturing system by tripling the size of the factories |

| 1975 | Changed the company name to Suzuki Kenji Iron Works Co., Ltd. Launched the manufacturing of food production machines and handmade shrimp-cracker making machines |

| 1976 | Introduced numerically controlled tool-machines (NC machines) earlier than our competitors |

| 1979 | Started the machining of car parts |

| 1981 | Obtained a patent for manufacturing automatic monaka producing machines |

| 1986 | Consolidated our two factories into a new factory (current factory) |

| 1990 | New President appointed; Introduced the latest equipment in the factory to enter new machining fields, such as the machining of car parts and equipment parts |

| 2002 | Acquired ISO 9001 certification |

| 2010 | Obtained various patents for new products in association with machining technologies, which were developed by the Automatic Confectionery Machine Division; Akabane Second Factory newly established |

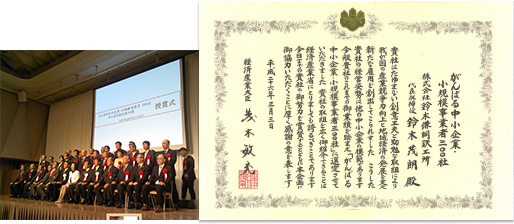

| 2013 | Received “Excellent SMEs (Small- and Medium-sized Enterprises) and Micro Enterprises Selection 300” award of the Ministry of Economy, Trade and Industry |

Copyright@SUZUKI KENJI IRON WORKS Co ,Ltd Co Ltd.All rights reserved